Wire Binding Documents Tips for all you need to know – Wire Binding documents can be a little trickier to master than comb binding documents, here are some wire binding documents tips to make your wire binding easier and produce neater documents.

How to get started for Wire Binding Documents Tips

First off make sure you are comfortable when binding this is especially helpful when binding for prolonged periods. The height of the desk you are using is very important, If it is too low you will hurt your back leaning over and if it is too high you will have difficulty operating the machine.

Before you start wire binding it is a good idea to make sure the margins are all lined up correctly. Do this by punching a scrap piece of paper and then check the holes are evenly spaced from the edges. You can then adjust the margin lever or paper guide if required.

Wire binding documents tips easy as 1, 2, 3!

1. Prolong the life of your Wire Binding Machine

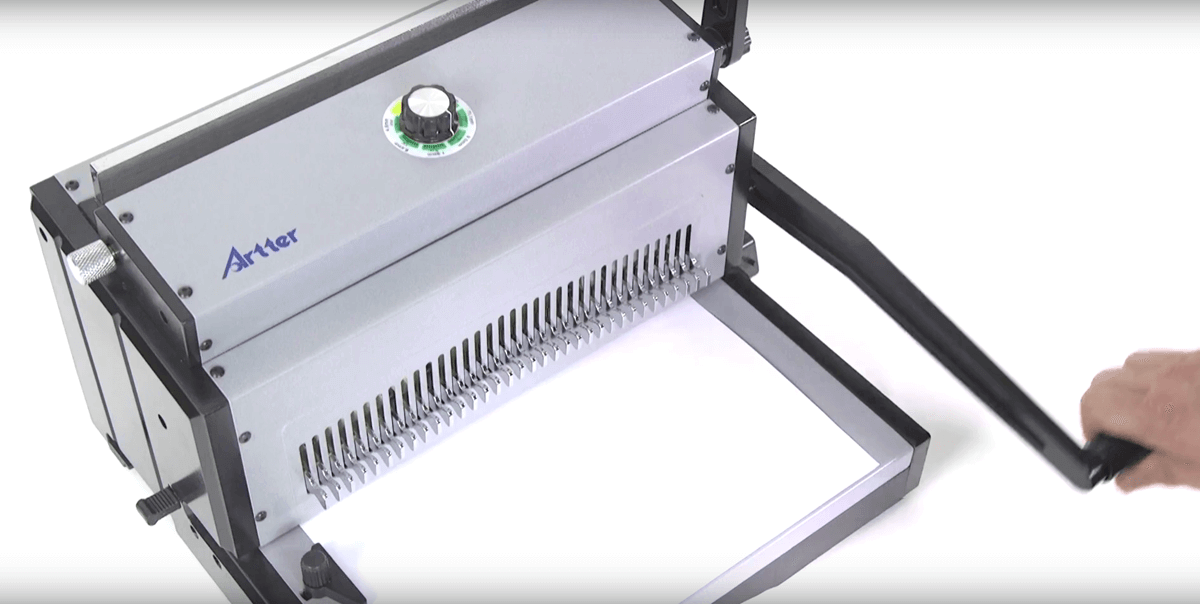

To prolong the life of your wire machine it’s recommended that you don’t punch the maximum amount of sheets in each pass as this puts extra strain on the mechanism and over time dulls the dies. Also, note that the maximum sheets for each machine is based on 80 gsm uncoated paper so for thicker or coated paper you should reduce the number of sheets accordingly. Due to their thickness and the material we also advise only punching two acetate clear covers at a time.

2. Try not to damage your Wire Binding Machine

It is easily forgotten about but a common cause of machine breakdown is a jam as a result of punching with the waste paper tray full. The tray should be emptied regularly as jams become more likely and the dies can be damaged or blunted over time if punching with a full tray. This is even worst on electric machines as you can’t feel the resistance that you would on a manual machine.

3. Hide the wire join to get a neat finish

For a neat finish after all the pages are punched always take the back cover and put it at the front of your document. This will then hide the wire join in the back pages once bound. Although difficult to explain this is clearly demonstrated on our wire binding machine videos.

Transferring your punched document with the wire inside to the clamp without it falling apart can be difficult. I find it easiest to thread the wire through holes and pinch the document tightly between thumb and first finger of your left hand. This should lock the wire and document in place and allow you to easily move the document into the clamp. Again this is clearly demonstrated on our wire binding videos.

4. Ensure the wire is clamped evenly

To ensure the wire is clamped evenly make sure that the wire is sitting flat on the bed of the clamp. If the wire does not close tightly enough then adjust the clamp slightly and try again. If the wire slips when clamping then friction tape (like self adhesive sandpaper) can be added to the sides of the clamp to help grip the wire.

If you need any help with our wire binding tips please just contact us to find out more or check out our wire binding videos. Also check out our how to wire bind a calendar and our wire size guide…

Contact NZ Binding For Any Enquires and Further Information

We hope you found this guide helpful. If you require further information, please do not hesitate to contact our team by using the online contact form below, using the chat service in the bottom right hand corner of your screen or give us a call at 09 972 0842.

Connect with NZ Binding on Facebook, LinkedIn, Google+, and Twitter.